SMART FACTORY SOLUTION

A breakthrough step in digital transformation of modern manufacturing.

In an increasingly fierce global competition, manufacturing enterprises not only face pressure in terms of cost, quality, and delivery time, but also must rapidly adapt to market fluctuations. The Smart Factory is a strategic solution that empowers businesses to improve management capability, optimize operations, and create sustainable competitive advantages.

The Smart Factory Solution is based on a comprehensive digital transformation platform, integrating digital technologies, real-time data, and Artificial Intelligence (AI) to upgrade traditional production management into an smart – automated – flexible operating model.

What is a Smart Factory?

A Smart Factory is a modern manufacturing model where people, machines, IT systems, data are seamlessly connected on a unified platform. All activities from planning, production, and quality control to maintenance and performance analytics are digitized, monitored, and optimized in real time.

Instead of managing based on experience and fragmented data, businesses can make decisions based on accurate, transparent, and instantaneous information.

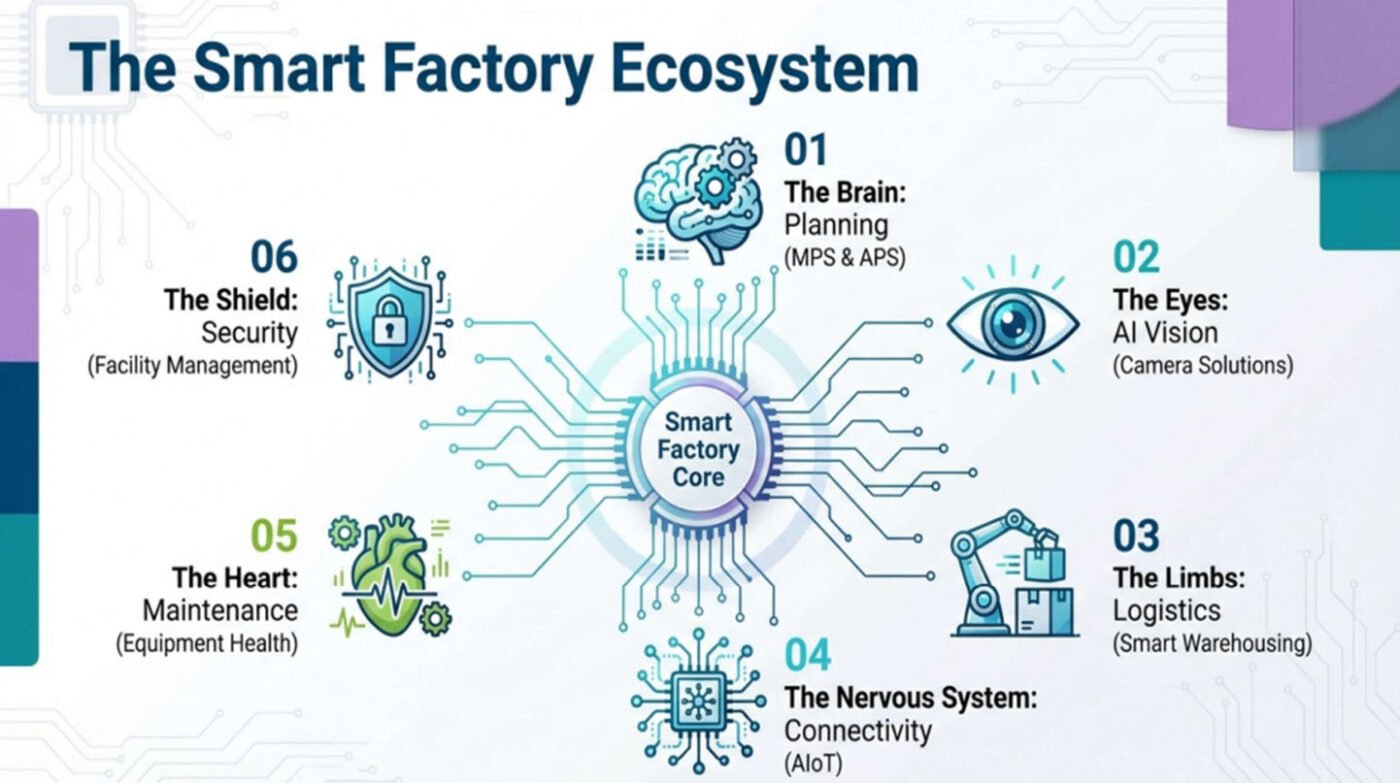

Overall Solution Architecture

The Smart Factory Solution is structured into four core layers:

-

- Production Planning & Optimization Layer

- Operations Monitoring & Process Standardization Layer

- Equipment Connectivity & OT Data Acquisition Layer

- Equipment Health and Maintenance Management Layer

These four layers are implemented through four core software solutions, capable of independent deployment or fully integrated into a unified platform.

1. MPS & APS Solution

Master Production Planning and Optimized Scheduling

MPS (Master Production Scheduling) and APS (Advanced Planning & Scheduling) serve as the central platforms for production planning and scheduling.

Key Functions:

-

- Master production planning based on orders, forecasts, and actual capacity.

- Detailed scheduling by machine, production line, shift, and resource availability.

- Optimize production schedules under complex constraints (capacity, material availability, changeover time, order priority)

- Run multi-scenario simulations (what-if analysis)

Technical Value:

-

- Reduce resource conflicts and semi-finished goods inventory.

- Increase planning accuracy compared to manual methods.

- Provide foundational input data for downstream monitoring and analytics systems.

2. SOP Copilot Solution

Smart Monitoring and Process Compliance Support

SOP Copilot is a solution designed to monitor shop-floor execution based on Standard Operating Procedures, combined with real-time production data.

Key Functions:

-

- Track SOP compliance by process step and workstation.

- Detect process deviations, abnormal operations, or standard violations.

- Generate instant alerts and provide context-aware corrective guidance.

- Support operator training and standardization of work instructions.

Technical Value:

-

- Standardize production quality at scale.

- Reduce dependency on individual operator experience.

- Enhance traceability and Root-cause Analysis capabilities.

3. Legacy PLC Connectivity Solution – Spiider Solution

Flexible OT Connectivity Without Replacing Existing Equipment

Spiider Solution acts as an OT Middleware layer that enables connectivity and data acquisition from older PLCs and multi-vendor industrial machines without requiring hardware upgrades or equipment replacement.

Key Functions:

-

- Multi-protocol connectivity (Modbus, OPC, proprietary protocols, etc.)

- Standardization of device data into a unified data model.

- High-stability real-time data acquisition from heterogeneous equipment.

- Secure segmentation between OT and IT networks.

Technical Value:

-

- Solves the legacy system integration challenge in existing factories.

- Reduces initial investment costs for digital transformation.

- Provides foundational data for MPS/APS, SOP Copilot, and APES.

4. Equipment Health Monitoring Solution – APES

Asset Performance & Equipment Health System

APES is an asset management and equipment health monitoring solution built on operational data and trend analytics.

Key Functions:

-

- Real-time monitoring of equipment operating status.

- Analyze vibration, temperature, current load, and duty cycles.

- Detect abnormalities and predict failures through Predictive Maintenance algorithms.

- Manage maintenance schedules, incident history, and equipment performance metrics.

Technical Value:

-

- Reduce unplanned downtime.

- Switching from periodic maintenance to predictive maintenance.

- Optimize maintenance costs and extend equipment lifespan.

The Smart Factory Solution is not simply a standalone software system, but an integrated manufacturing management architecture in which MPS & APS – SOP Copilot – Spiider – APES work seamlessly together to create a connected, transparent, and continuously optimized manufacturing environment.

This is a solid technical foundation that enables enterprises to progressively advance toward intelligent, autonomous, and sustainable production in the era of digital industry.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)