SMART PRODUCTION PROCESS MONITORING SOLUTION – SOP COPILOT

As factories face increasing pressure for higher productivity, quality, and process transparency, traditional manual monitoring methods have revealed many limitations. SOP Copilot – the intelligent production process monitoring solution implemented by IIQ was created to help enterprises standardize operations, improving efficiency, and promoting digital transformation in manufacturing.

Current Situation and Challenges of Factories

Most factories still rely heavily on manual data collection, resulting in delayed information, low accuracy, and limited transparency. The traditional production model can no longer meet increasing demands for efficiency, consistency, and traceability.

In addition, enterprises struggle to answer critical operational questions such as:

-

- What is the actual cycle time at each workstation?

- Where are the production capacity bottlenecks?

- Which process steps are frequently skipped or performed incorrectly?

These issues highlight the urgent need for a detailed, real-time monitoring solution that is easy to implement while remaining cost-efficient.

SOP Copilot – Smart SOP Compliance Monitoring Assistant for Factories

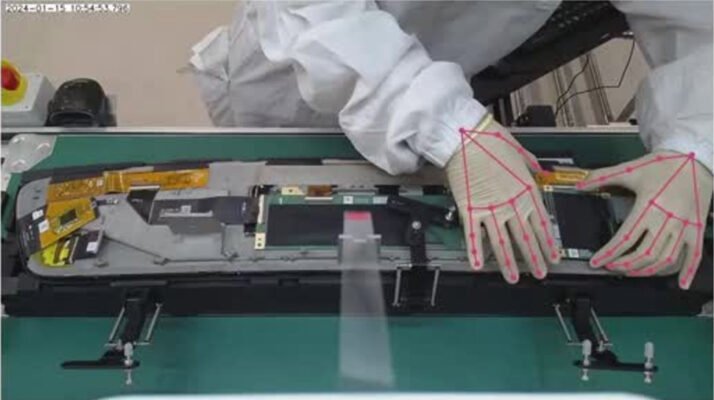

SOP Copilot is a production process monitoring solution based on AI-powered industrial cameras and control compliance with standardized operating procedures (SOP) at each workstation.

The system focuses on detailed monitoring of critical operation points such as hand movements, positions, and execution sequences to ensure that no step in the production process is skipped or performed incorrectly.

Key Features of SOP Copilot – Production Process Monitoring

Detailed SOP-based Monitoring

SOP Copilot continuously tracks each worker’s actions against the established SOP. When an incorrect action or a missing step is detected, the system instantly triggers an alert with a red-light signal, allowing errors to be prevented directly at the workstation.

Cost-effective performance improvement

The solution features a lightweight configuration and leverages existing camera infrastructure, enabling manufacturers to improve product compliance rates and increase productivity without significant investment in new equipment.

Fast and flexible deployment

SOP Copilot can be installed without stopping the production line and integrates easily with existing camera systems. This minimizes operational disruption and shortens the time required to bring the system into operation.

Simple and intuitive user interface

The system is designed with a clear, user-friendly interface, allowing supervisors to easily configure, monitor, and utilize data through the web-based platform and centralized dashboard.

Smart Dashboard and Reporting

Through its reporting system and dashboards, SOP Copilot enables managers to:

-

- Detect which process steps are most prone to errors or omissions.

- Analyze error trends over time.

- Optimize training, improve processes, and allocate resources effectively.

The monitoring data becomes a critical foundation for decision-making based on factual data rather than subjective experience.

Value Delivered by SOP Copilot

SOP Copilot helps enterprises:

-

- Increase productivity and operational efficiency.

- Reduce operator errors and corrective costs.

- Shorten machine downtime.

- Strengthen product quality control.

- Ensure continuity in production activities.

Beyond supporting production operations, the monitoring system improving before and after production, reduce total operating costs and enhance long-term competitiveness.

An Inevitable Trend in Smart Factory

The rapid development of AI-powered industrial cameras and machine learning is driving production monitoring systems to become increasingly intelligent and automated. As Vietnam’s manufacturing industry continues to expand and shift toward high technology, SOP Copilot is a suitable solution for enterprises aiming to keep pace with smart factory trends and sustainable digital transformation.

IIQ – Partnering with enterprises in digitalization and production optimization.

SOP Copilot is not just a monitoring system; it is an intelligent assistant that helps factories operate more efficiently, transparently, and consistently every day.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)