Smart Warehouse Management System – WMS

WMS (Warehouse Management System) is an intelligent warehouse management software that helps businesses monitor, control, and optimize all warehouse operations – from receiving, storage, and inventory checks to shipping – automatically, accurately, and in real-time.

IIQ’s WMS solution is developed on a modern technology platform, supporting multi-warehouse and multi-location management, and seamlessly integrating with the company’s ERP, SCM, and CRM systems.

The WMS system helps to:

- Increase warehouse operational efficiency through automated processes.

- Reduce errors and inventory loss with real-time data management.

- Accurately control inventory down to each location, item code, and product batch.

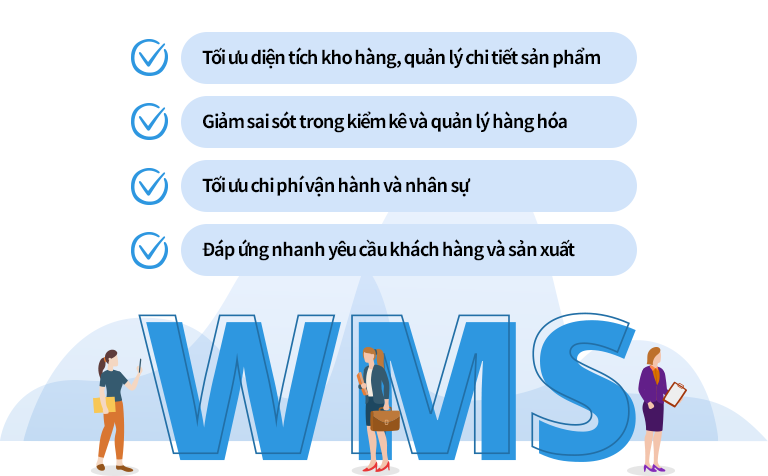

- Optimize operating costs and reduce reliance on individual experience.

Benefits of Implementing WMS

✅ Improved operational efficiency: Reduces 30-50% of handling time for inbound and outbound goods, thanks to guided workflows and intelligent routing within the warehouse.

✅ High inventory accuracy: Minimizes discrepancies between data and actual stock through automatic updates using barcodes/QR codes.

✅ Transparent control & Traceability: All transactions are recorded and traceable — from the operator to the storage location.

✅ Reduce operating costs: Minimizes product loss, saves labor, and optimizes storage space.

✅ Easy scalability & Integration: Open system easily connects with ERP, SCM, TMS, POS, and devices such as barcode scanners, scales, robots, and IoT devices.

Target Customers

- Manufacturing, trading, distribution, logistics, and e-commerce businesses

- Warehouse centers and distribution centers (DC)

- Companies with multiple warehouses, branches, or operating along a supply chain.

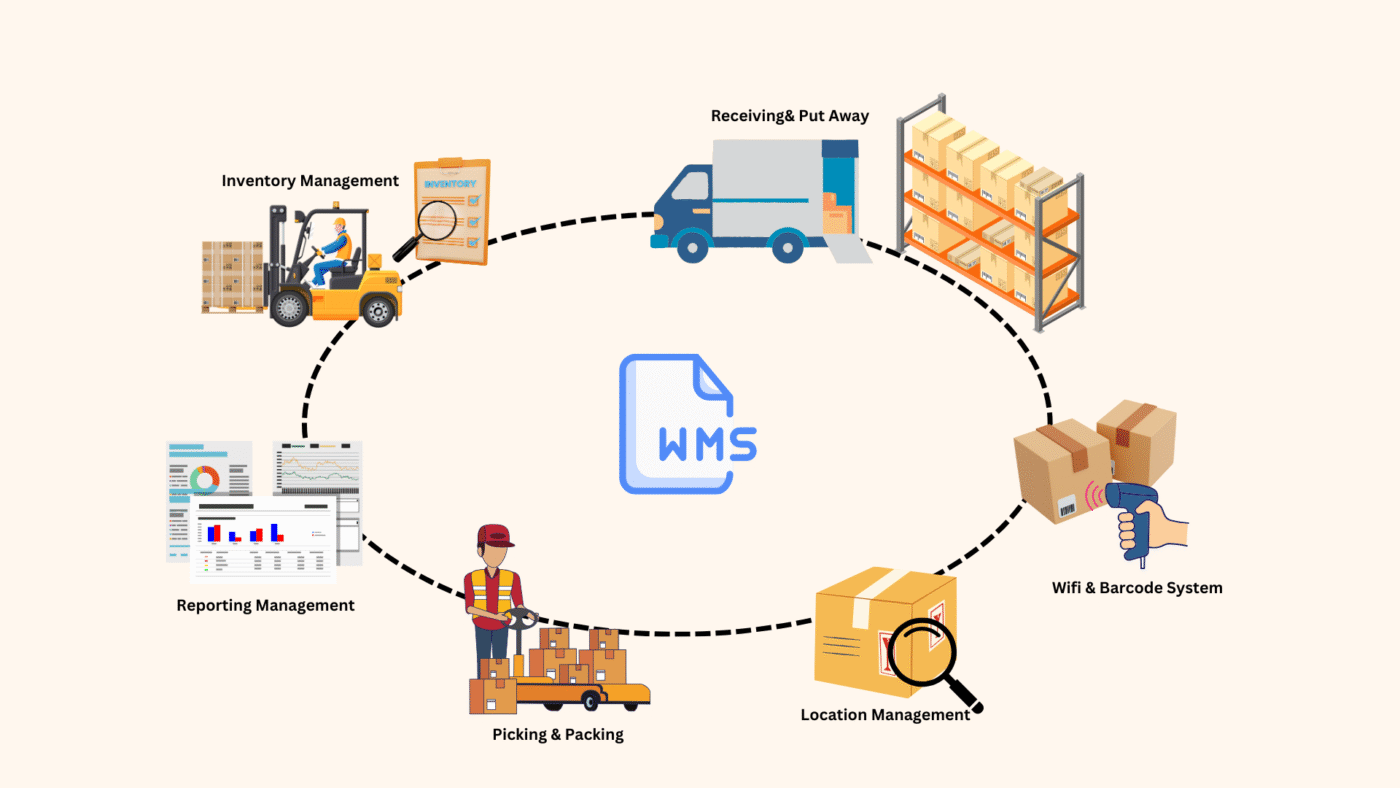

Key Functions of the WMS System

- Inbound Management: Track receipts, inspect incoming goods, automatically allocate storage locations, and support barcode/QR code scanning.

- Outbound Management: Manage outbound orders, assign optimal picking locations, inspect, pack, and confirm shipments efficiently.

- Inventory Management: Monitor real-time stock levels, analyze quantities, conditions, expiration dates, and receive alerts for slow-moving items.

- Stock Taking & Reconciliation: Automatically reconcile actual stock with system data, supporting inventory by area, product group, or scheduled periods

- Location & Slotting Management: Manage warehouse structure by floor, rack, and bin; suggest optimal storage locations based on inbound/outbound frequency.

- User & Task Management: Assign user permissions, track employee performance, and monitor task completion times.

- Traceability: Track and trace products’ lifecycle and history.

- Analytics & Reporting: Provide reports on inbound/outbound/stock levels, employee performance, inventory turnover, and stock forecasting.

- Integration with other systems: Easily integrates with ERP, SCM, TMS, POS, and other systems.

IIQ’s WMS – Warehouse Management System is a comprehensive digital transformation solution for warehouse operations, enabling smart management, cost savings, increased productivity, and absolute data accuracy.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)